Carboxymethyl Cellulose (CMC)

CMC is a derivative of natural cellulose with an ether structure obtained through chemical modification. It is a water-soluble glue that can be dissolved in cold and hot water. Its aqueous solution has the functions of bonding, thickening, emulsifying, dispersing, suspending, stabilizing, and film-forming.

Carboxymethyl Cellulose (CMC) Application scope

A hydrosol with excellent properties.

Function

As a treatment agent for drilling mud, it has good salt resistance and temperature resistance, high pulping rate and small filter loss. It can be used in the preparation of various drilling fluids, and can maintain and improve the performance of drilling fluids during the drilling process.

Dosage: 0.4-0.6%.

Application method

There are basically two ways to use or dissolve sodium methylcellulose: the first is direct dissolution; the second is to mix sodium methylcellulose thoroughly and evenly with other dry powder materials, and then dissolve it in the solution. Please see below for details:

1. Mix sodium methylcellulose directly with water to prepare a paste glue and set aside.

When preparing sodium methyl cellulose paste, first add a certain amount of clean water to the batching tank with a stirring device.

With the stirring device turned on, slowly and evenly spread the sodium methylcellulose into the batching tank.

Keep stirring until the sodium methylcellulose and water are completely integrated and the sodium methylcellulose can be fully dissolved.

2. Mix sodium methylcellulose with other dry raw materials in a dry method, and then put it into water to dissolve.

During operation, first put sodium methylcellulose and dry raw materials such as materials in a stainless steel mixer in a certain proportion, close the top cover of the mixer, and keep the materials in the mixer in a sealed state.

Then, turn on the mixer to fully mix the sodium methyl fiber and other raw materials.

Then, slowly and evenly sprinkle the mixed sodium methylcellulose mixture into the batching tank filled with water, and stir continuously. The subsequent operations can be performed with reference to the first dissolution method mentioned above.

Physical and chemical indicators

| CMC-HV | CMC-LV | |

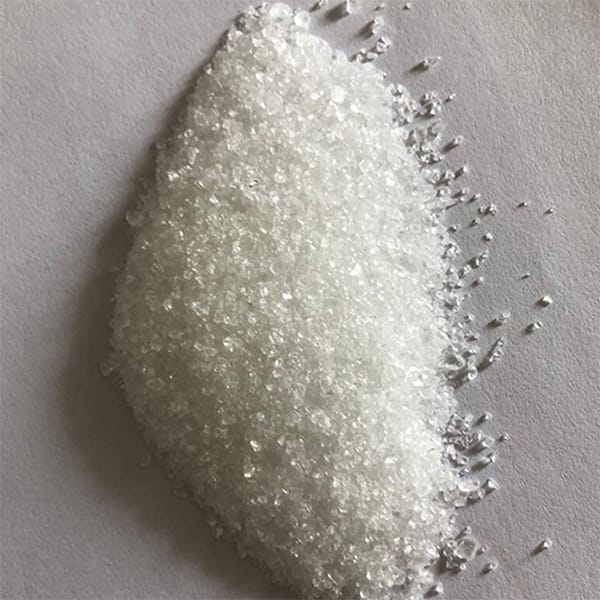

| Traits | White or light yellow powder | white or light yellow powder or granules |

| Moisture | Up to 10.0% | Up to 10.0% |

| pH | 7.5-9.5 | 7.5-9.5 |

| Degree of substitution | Minimum 0.70 | Minimum 0.80 |

| purity | Minimum 65% | Minimum 60% |

Store

CMC should be stored in a cool, dry place with a temperature below 40°C and a relative humidity below 75%.

Under the above conditions, it can be stored for 24 months from the date of production.

Package

Packed in 25KG (55.1lbs.) composite bags and valve bags.